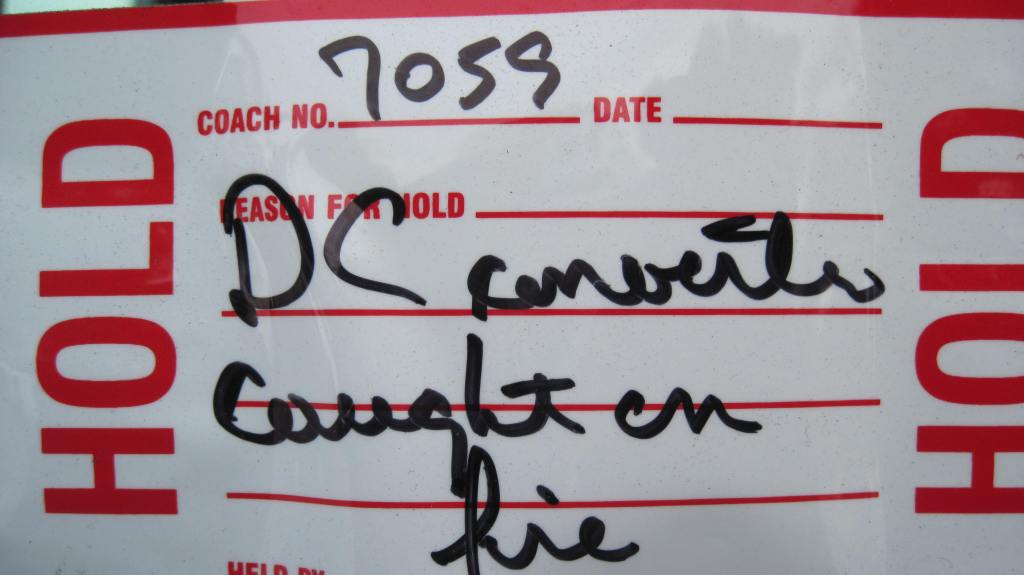

The installation of cameras on the front windscreen has had one beneficial effect. Those monitoring our pull-out time see how much extra time is required to move deficient coaches out of the way. With trolleys at Potrero, we have so many coaches dead on the tracks that we are trapped in a canyon or gauntlet of unmoving buses, such that if the lead coach in front of us is caught in restrictive mode at start-up, we are blocked from pulling out on time.

A good yard starter is found turning on coaches well in advance of their pull-out in the morning to see if a reboot is necessary. The installation of computers and memory chips on buses may be great for global positioning monitoring and data checking brake function, speed, and door-opens, but these devices can create hassles with morning sickness on the equipment when it has been a cold night with heavy fog. Moisture adhering to carbon on the various components and electrical sensor points creates annoying warnings, such as hot body, that cut into the calm of morning pull-out. (I have always wanted a hot body, but not on my assigned coach!)

In the afternoon, finding a good coach can be like hide-and-seek, and I was blessed with being able to talk to my leader on her cut-in pull-out as to why she was having difficulty making the pull-out on time. The secret to making sure all is well is to allow for more than ten minutes of extra time when arriving to the pre-op point. If this is not possible, then communicate the problem in a way that does not ruffle feathers. Not a good idea to upset the shop and crew working on your equipment before you pull out in the morning.

Oh gee, the coach is in restrictive mode, or the inductive dial is turned to the right. Oh, the coach was turned on in day run. Did I check to see if I was on night run with all my lights on? And the pre-op list goes on. The key to having no trouble has been to show up early to make sure the coach is on and not in restricted mode. I have to check the master dial and make sure the coach is not in neutral on the ETI or in neutral on the Flyer. I also have to make sure the bus was not left on in EPU (emergency power unit or battery mode) last night, or else I am not going anywhere. The precious extra fifteen minutes we are given on our paycheck to pre-op the coach comes in handy when we have to get the yard starter to call the shop to assist us with a jump or a reboot of the circuit board to get us going. If I wait until the last moment to reprogram the fare box, I could hear a nasty alarm that the box is open or has no power.

As creatures of habit, we usually save the fare box to last, but this, too, can lead to a late pull-out. So the key is to show up before pull-out to make sure the bus is in gear, in power, and programmed from head sign to fare box so that no surprises await. Checking the wipers to see that they actually clean the window and the mirrors and that they are in a good alignment, can also dog us in being late. Especially if it has been dry, and the wipers haven’t been used for a long time. The wash rack throws mirror arms out of alignment.

If the wipers were left on at a terminal during a misty rain, the window can be smeared with dull blades. And finally, deployment of the lift is icing on the cake to determine if I will have a day of service or a day of waiting for the shop and giving the bus and operator behind me a double passenger load.

I am happy to say I have kept the Zen in pulling out on time over the years and have had very few LPOs to my name. Cutting in on the line is an art in and of itself. Just as with a switchback, entering the line a few minutes late or behind time is a good idea for not getting ahead of oneself, which is to say that an empty bus moves up in headway faster than the following coach that already has a load. Being aware of this helps keep the Zen with your follower.